What is standing seam Roofing system?

Standing seam metal roofing is a concealed fixed roof system which features vertical ribs with a flat space or pan in between. The side edges of one roof panel are zipped or seamed along the length with the adjoining roof panels. The roof panels are attached to the purlins or secondary members with specially designed clips or clamps. The concealed fix system requires no piercing fasteners and helps provide weather tightness and superior resistance to wind uplift.

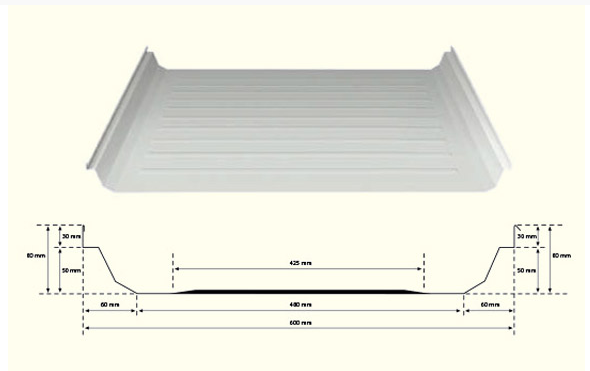

A: Standing seam roof profile

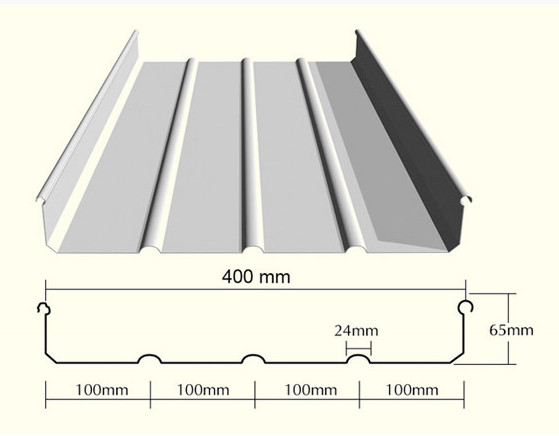

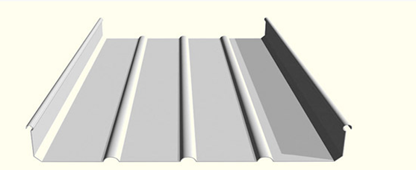

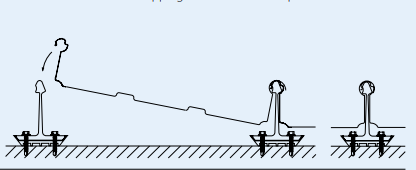

A: Standing seam roof profile  B: Concealed fixing of standing seam roof profile on clips

B: Concealed fixing of standing seam roof profile on clips

What are the advantages of standing seam Roofing system?

Concealed fixed roofing system

Standing seam roofing comes with concealed fix system which requires no piercing fasteners and helps provide weather tightness and superior resistance to wind uplift. With no exposed fasteners, the straight lines of your roof remain clean and smooth.

Allows for Thermal expansion and contraction

This system is fixed over specially design clips such that it allows for lateral of roof movement which results from the thermal effect

Design flexibility Standing seam roof systems available in tapered and curved sheets to fulfil the most challenging design criteria. Suitable for roofs with low slopes. On-Site Roll-Forming Standing seam roof systems can be manufactured on site using mobile roll-forming technology, which not only gives single length from the ridge of the roof to the eave, but also helps to make it a leak-proof structure with better control over quality installation. Sleek, consistent, & modern look Standing seam roof system is suitable for architectural applications because of its modern and clean look. In addition to the sleek, straight lines offered by this roof system, the roof can come in virtually any color, including custom colors, to match any structure.High design flexibility with multiple profile shapes makes it an architecturally superior roofing profile Longevity Metal roofs are already a long lasting and low maintenance roofing solution, especially when compared to other roofing types. Since standing seam roofing comes with concealed fix system which requires no piercing fasteners, there are no instances of damaging or loosening of fasteners or the roof surface. Standing seam roof system’s design flexibility, weather tightness and versatility makes it an excellent choice for architecturally superior buildings for commercial, industrial and infrastructural applications Tata BlueScope Steel offers the most advanced and versatile standing roof systems in India with and MR 24 Roofing system and LYSAGHT® FLEXLOK 400 roofing system MR 24 360 degree Standing Seam Roofing System The MR-24® Roof System is like a monolithic steel membrane, covering your entire building. The panels are joined together with a Pittsburgh 360 degree double-lock standing seam, and fastened to the purlins with a unique clip formed into the seam. Independent surveys show that MR-24® Roof System is the most specified standing seam roof in the market, with more than two billion square feet installed since its introduction in 1969.