India’s urban growth story today is being shaped by much more than just infrastructure; it’s also being built by the people, their vision, and the collaborative spirit that powers each structure. The Pune Metro is a remarkable testament to this – an infrastructure achievement that exemplifies what becomes possible when architects, engineers, planners, and execution teams collaborate with clarity and purpose.

More than a mode of transport, it stands as a symbol of how human coordination and technical excellence together can build systems that are resilient, inclusive, and enduring. Every curved roof, synchronized panel, and seamless junction reflects the collective intelligence and shared commitment of those who built it.

National recognition for engineering excellence

Pune Metro (Phase 1) has recently won the “Project of the Year – Metro” award at the 23rd Construction World Global Awards 2025, as part of the 11th India Construction Festival. This is our third consecutive honor for the Pune Metro contribution, following earlier recognition at the India Infra Forum on Urban Transportation Projects (EPC World Awards, Feb 2025) and the BAM Awards 2025. These accolades reflect product excellence, but more importantly, celebrate the spirit of collaboration that defines our approach to infrastructure.

Designing for a cultural metropolis: Vision translated through collaboration

Renowned architect Hafeez Contractor saw each metro station as more than just a building; as a public space that resonates with the city’s cultural soul. His vision was to shape landmarks that commuters don’t just pass through, but connect with. Drawing from Pune’s heritage of education, innovation, and art, the station designs incorporated flowing lines, bold forms, and expansive volumes to mirror the spirit of the city.

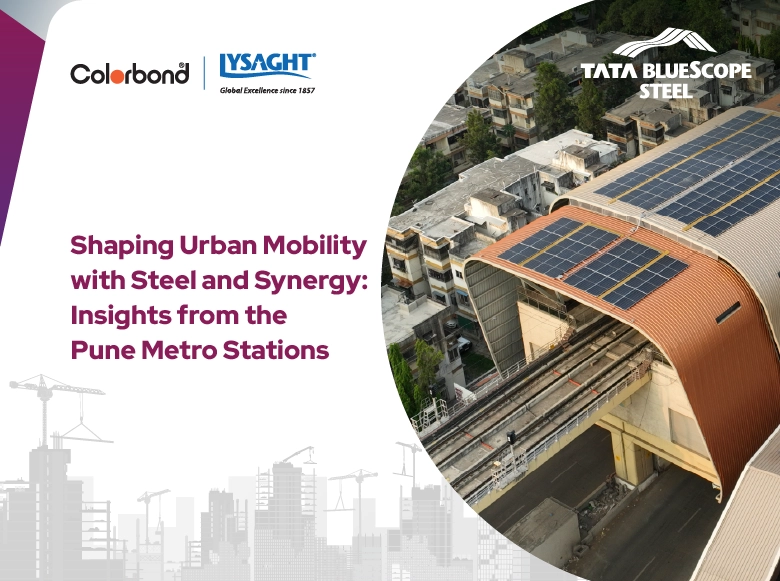

Translating this design intent into physical form required materials and systems that are structurally sound and visually expressive. Tata BlueScope Steel worked shoulder-to-shoulder with design teams from the conceptual stage, ensuring materials, finishes, and engineering decisions remained faithful to the original vision. COLORBOND® steel, in unique shades such as Copper Penny, Champagne Gold, and Sky Ridge, was selected for its aesthetic coherence with Pune’s landscape as well as its durability and thermal efficiency.

Smart infrastructure enabled by collective intelligence

Future-ready cities require infrastructure that goes beyond the immediate. Tata BlueScope Steel integrated a non-invasive solar panel mounting system that used custom-engineered aluminum clamps, fixed with friction bolts onto LYSAGHT KLIP-LOK® 700 panels. This allowed solar modules to be installed without piercing the roof surface, preserving leakproofness while enabling renewable energy adoption.

This blend of form, function, and future-readiness is made possible by interdisciplinary teamwork, from material engineers to field installers, working cohesively toward a shared vision. This is beyond just cost or capacity. It’s about how intelligently and responsibly each system can support the needs of a growing population.

Collaboration: The human force behind the steel

Every element of the Pune Metro project was made possible by a network of committed individuals – engineers, architects, planners, construction workers, and government authorities – working in unison toward a common goal.

The technical team of Tata BlueScope Steel coordinated closely with contractors from Shapoorji Pallonji and officials from Pune Metro Rail Corporation Limited (PMRCL) to ensure structural alignment with design intent. At the Nal Stop station, when heavy rainfall delayed installation, a joint team huddle resolved a complex roofing alignment challenge within hours, using a mobile crimping station and synchronized deployment of curved panels.

Local labor crews, trained specifically in handling KLIP-LOK® panels and crimped installations, showed tremendous adaptability in managing the scale and detail required. “Every curve had to be exact – there was no margin for error,” recalls one of the project engineers. “This project demanded both precision and pride.”

Such ground-level coordination, knowledge transfer, and execution ensured project success and also empowered the workforce to do their jobs better.

Experience in motion: Public spaces that invite and inspire

The spacious design, controlled climate, and color-synchronized structures offer more than convenience; they instill civic pride. The architecture encourages seamless movement while creating an uplifting spatial experience, reinforcing the idea that public infrastructure can and should be dignified, welcoming, and well-designed.

This transformation of daily commute into an inspiring experience is a powerful narrative in itself. It signals the rise of cities that put people first – in every brick and beam.

Scaling urban progress through shared effort

The contribution of Tata BlueScope Steel to the Pune Metro is part of a larger story, one that includes over 135 metro stations across India. Every project becomes a node in a national network of progress, skill development, and smarter urbanization.

Infrastructure like Pune Metro Station does more than move people. It fuels economies and connects communities. It demonstrates what is possible when vision aligns with execution, and when engineering respects both human and environmental needs.

Engineering resilience: Built by people for scale, safety, and the next century

Pune’s monsoon intensity, rising urban temperatures, and station elevations presented unique challenges. Each station, approximately 140 meters long and 21 meters wide, had to withstand wind speeds of up to 39 m/s and accommodate large footfalls daily.

To meet these demands, LYSAGHT KLIP-LOK® 700 concealed-fixed cladding was used extensively. Its 43 mm high ribs and 233 mm wide pans offer both strength and enhanced water drainage. Importantly, the profile was roll-formed on site and installed in long, joint-free lengths. This eliminated leak-prone overlaps and ensured continuous water shedding, which is critical during Pune’s heavy rains.

Purlin spacing was optimized to 1400 mm to enhance wind uplift resistance without compromising the architectural openness of the roofs. Multiblock connections were detailed with unique flashing systems to ensure seamless integration of curved and straight panels, preserving visual uniformity and ensuring no internal seepage.

Final reflections

The Pune Metro Stations’ go beyond being just an infrastructural project; it is a legacy being built. It reflects the power of collaboration, the importance of cultural sensitivity in urban design, and the role of engineered materials in delivering civic value. Tata BlueScope Steel stands as a collaborative enabler – supporting architects, engineers, and construction teams throughout India’s urban transformation.