Advantages

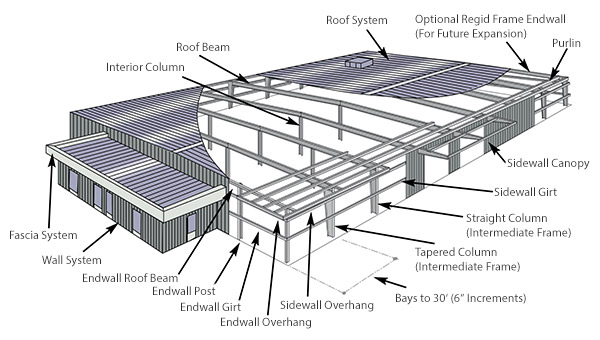

Design Flexibility

Combines the practicality of a rigid frame with virtually unlimited design flexibilityUninterrupted Wide Spans

Clear span framing systems allow maximum interior space utilisation. This is particularly important in manufacturing plants, warehouses, offices and retail stores where uninterrupted space requirement is critical.Easy Extensions & Expansions

The width extension matches the eave heights, and roof slopes facilitates additional space for future expansion.Improved Corrosion Protection

The mainframe sections come with primer coat, which protect the base steel for much longer time than any conventional fabricated steel structure.Longer Life with Minimum Maintenance

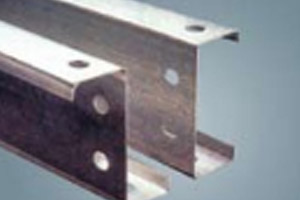

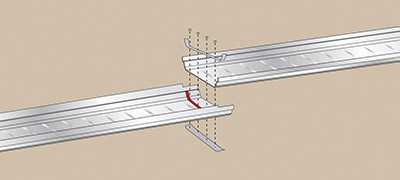

BUTLER® Structural System comes with galvanised purlin and girt known as CEE-plus™ & ZED plus™, which last much longer without any requirement for regular maintenance, when compared with conventional unprotected structural elements.

Advantages

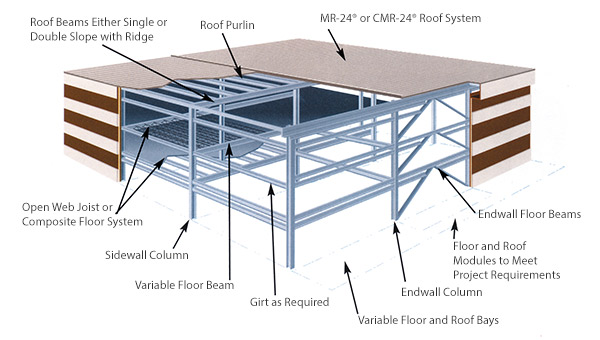

Monolithic Roofing System

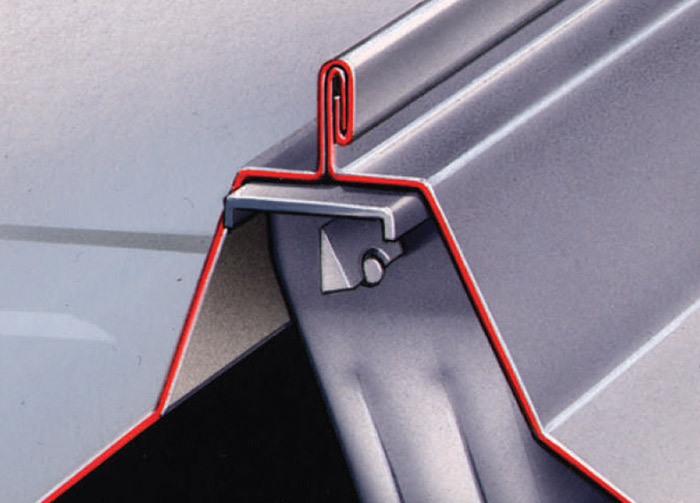

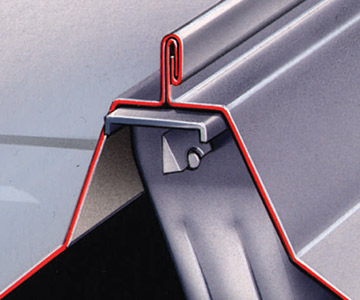

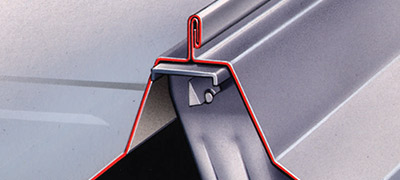

MR-24® Roof System acts as a monolithic steel surface covering your entire building and providing superior protectionDouble-lock seam Joint

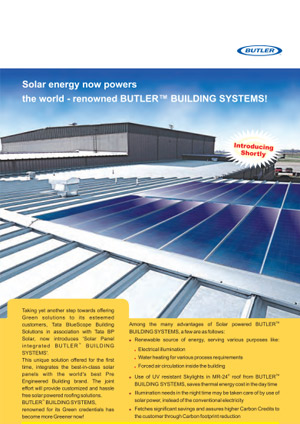

Creates an exclusive Pittsburgh 360-degree double-lock seam, with the final 180 degrees field rolled, for superior performance, protection and weather tightness.Contributes to Energy efficiency

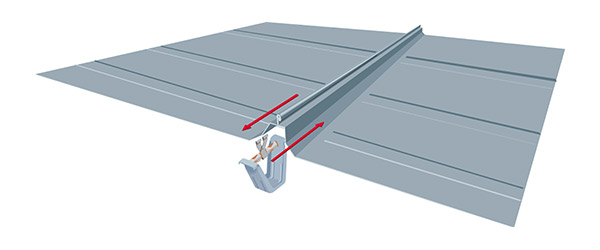

MR-24® Roof System accommodates additional Roof insulation thicknesses to enhance energy efficiency. Available in several cool colors with high SRI values, for added energy savings.Roof movement for varying temperatures

Specifically designed with moveable clips to accommodate roof movement under changing temperaturesStrength and weather tightness at end laps

Most manufacturers locate panel splices at exactly the same position across the entire roof. This creates a condition where four panel corners must be joined at the same location, making it almost impossible to seal and keep weather tightPerfect alignment and installation

Factory-punched panels and structural members assure proper alignment and accurate installation

Advantages

Deep corrugations for extra strength

BR-II™ 900 roof panel offers the deepest and a wide corrugation coupled with a high tensile steel base of minimum 550 MPa yield strength providing additional strength in comparison to any other industrial profile for both wind uplift and roof trafficEnhanced weather tightness

Anti-capillary groove for leak proof performance, which can also be used for sealant placement to ensure weather tightnessPerfect alignment and installation

BR-II™ 900 roof system is also available in factory punched option to assure perfect alignment and accurate installationAdditional support against roof traffic

To provide additional support against roof traffic, BR-II™ 900 roof panels incorporate a “return leg” on all side lap connections. Roof panels without return leg often separate under fastener installation or roof traffic.Improved Thermal Performance

BR-II™ 900 profile comes with THERMATECH™ Solar Reflectance Technology that lowers surface temperature by absorbing lesser heat from the sun. It keeps both roofs & buildings cooler at reduced energy costs.

Features

- Simple, low-cost fixing so it is economical to install

- Excellent spanning capacity

- Manufactured from high strength ZINCALUME® steel or COLORBOND® steel

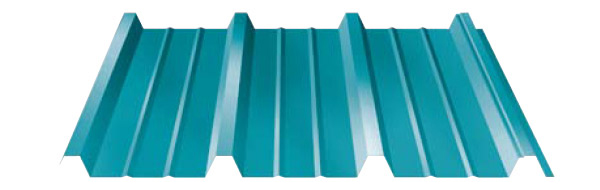

Features

- Strong and lightweight

- Strongest cladding profile which can withstand high wind load, snow load or impact load

- Unique anti-capillary side-lap which makes it leak-proof

- Manufactured from high strength ZINCALUME® steel or COLORBOND® steel

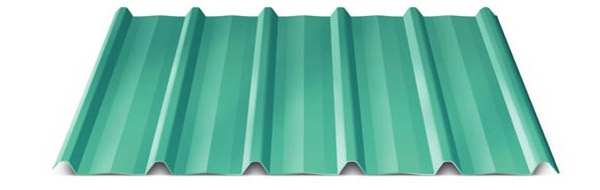

Features

- Strong and lightweight

- Wider profile covers large surface area

- Wall panels can be installed in horizontal as well as in vertical direction

- Can be curved for stylish architectural design

- Manufactured from high strength ZINCALUME® steel or COLORBOND® steel

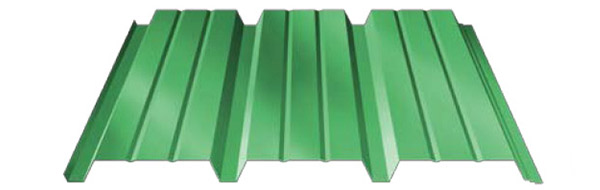

Features

- Engineered to withstand high wind load and pressure

- Wide pan visibility gives an aesthetically pleasing look to the exterior of the building

- Fewer fasteners than most ribbed panels

- The deep 38 mm corrugations provide strength to resist billowing when the fasteners are fixed

- Fasteners are recessed deep in the corrugation, it gives walls an attractive uniform pattern

- Manufactured from high strength ZINCALUME® steel or COLORBOND ® steel

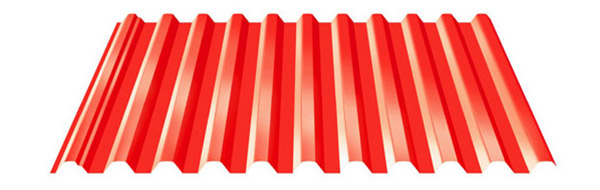

Features

- Attractive multi ribbed profile which is quick and easy to install

- Light weight and economical profile which covers wide surface area

- Manufactured from high strength ZINCALUME® steel or COLORBOND® steel

Features

- Provides easy solution for false ceiling and wall partition

- Panels can be installed in horizontal as well as in vertical direction

- Manufactured from high strength ZINCALUME® steel or COLORBOND® steel

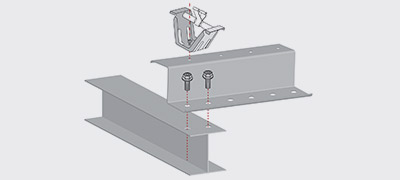

Features

- Manufactured from high tensile galvanised steel ( with 120 gsm, 345 Mpa) conforming to ASTM A 653M – 04a Gr. 50 Factory pre-punched system for easy and accurate installation results

- World class quality control system to avoid any dimensional variations during production

- The inclined lip helps in best nesting capability for easy transportation in bundles and in kits

- Available in a wide range of dimensions. This helps in manufacturing the most economical engineered building structure

- Tested and proven worldwide

- Fewer temporary props and bearers are required under the formwork deck, which provides weather protection for a safe work environment, both above and below the floor

- The embossments on top & sides of the ribs provide added grip and minimise slip by creating a bond with concrete as done with normal reinforcement

- Provides permanent formwork as well as positive reinforcement

- Does not require erection, removal, handling or storage of timber / steel formwork as required in conventional concrete slab construction, which saves valuable time

- Clean, uniform and attractive ribbed underside (soffit) for exposed situation reduces the cost of ceiling finishes

Key Differentiators

MR-24® Roof Clip allows free thermal movement of 21/2 inches

MR-24® Roof Clip allows free thermal movement of 21/2 inchesTruly floating standing seam roof system

MR-24® roof clip allows roof to expand and contract with changing temperatures. The highest thermal movement of roof clip negates the need for an expansion joint upto 500 ft in double slope buildings, which assures long term leak-proof performance. No measuring, marking and drilling on site minimises chances of error

No measuring, marking and drilling on site minimises chances of errorFor a truly E-engineered building

All secondary structural members are pre-punched for fixing the roof clips, structural components and accessories accurately. The pre-punched system does not require extensive field modifications and helps to provide an error-free building. BUTLER® Sealants

BUTLER® SealantsAssures leak-tight performance

The BUTLER® sealant has been developed by the BUTLER® Research and Development Centre. It has a higher butyl rubber percentage that enables leak-tight sealing at the joints. BUTLER® Curb Industry Standard

BUTLER® Curb Industry StandardFully engineered

BUTLER® roof curbs are designed to float along with the roof system to give leak proof and maintenance free life for much longer time than any other building system. BUTLER® SCRUBOLT Industry Standard

BUTLER® SCRUBOLT Industry StandardMaintains Incredible Strength

SCRUBOLT™ is another reason for BUTLER® BUILDING SYSTEMS to perform much better than any building system. The fasteners are designed to take twice the pull out strength than any conventional fastener. Precise Installation and Long Term Corrosion Free Performance

Precise Installation and Long Term Corrosion Free PerformanceFor superior corrosion resistance

BUTLER® BUILDING SYSTEMS comes with high tensile galvanised steel purlin and girt with a coating mass of 120 gsm for better strength and corrosion resistance. The purlins are designed and their shape is modified & tested over a number of years. BUTLER® Shot Blasted Frame

BUTLER® Shot Blasted FrameFor better paint adhesion

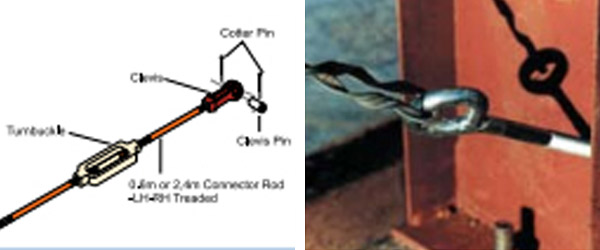

Our frames are thorough blast cleaned by shot blasting method (an optional feature) to achieve surface preparation upto SA- 2.5 to receive a coat or primer, which protects the steel from corrosion. BUTLER® Steel-Rod Bracing Industry Standard

BUTLER® Steel-Rod Bracing Industry StandardFor solid reinforcement

The BUTLER® steel rod bracings with Clevis Assembly and Turn buckle does not stretch or deform during or after installation. These specially designed rod bracings do not require retightening multiple times during erection and retain their original strength and tightness. BUTLER® Louvres

BUTLER® LouvresFor better air circulation

LOUVREMAX™ system is a specially designed water resistant louvre, an outcome of years of experience and extensive research, which delivers the best ventilation performance. SKYWEB ll® Passive Restraint System

SKYWEB ll® Passive Restraint SystemAssures complete peace of mind

The mandatory use of personal protection equipments, use of SKY-WEB® II fall protection system, usage of boom lifts, telescopic cranes and regular training of erection crew enables us to complete projects in a safe manner.

Boeing, TATA State-of-Art Aerospace Facility in Hyderabad by Tata BlueScope Steel PEB Solutions

In November 2015, Boeing and Tata Advance Systems announced a joint venture for manufacturing aero structures and collaboration on integrated systems development opportunities in India.View Case Study

Right Match for a World-Class Manufacturing Facility

When Mr. Sanat Bhattacharyya, Managing Director and Chairman, Arc Tec Systems Limited, bought the prime plot at MIDC Complex- Butibori, Nagpur for the company’s first manufacturing facility, his vision was clear. View Case Study

Leak-proof Roof System enables Nivea to meet their productivity goals!

Beiersdorf AG, parent company of Nivea is one of the world’s leading international skin care companies. View Case Study

Proven integrated business processes deliver on-time project completion

Vinplex India Pvt. Ltd. incorporated in 1996, leases warehouse spaces in and around the industrial hub of Chennai. View Case Study

Innovative safety approaches impresses GE India

GE India Industrial Pvt. Ltd. was planning to set up a manufacturing facility at Chakan, Pune, India.View Case Study

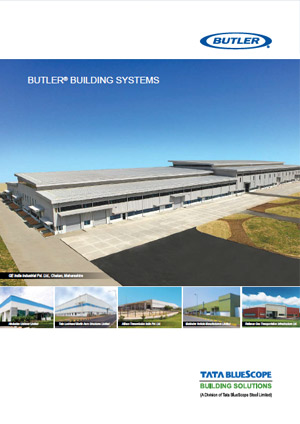

Superior Solution sets a Benchmark for Indian Warehousing Industry

Tata BlueScope Building Solutions builds India’s first Free Trade and Warehousing Zone at Panvel, Navi Mumbai for Arshiya International Ltd. View Case Study

Redefining Industrial Construction – “Concept to Completion in 60 Days”

The CLS Project of Hindustan Unilever Limited is one of the largest projects located in the developing industrial area of Haridwar, which is setting an example for its Project Management, Design and Engineering brilliance. View Case Study

East West Gas Pipe Line Project Wins PEB PROJECT OF THE YEAR AWARD

The magnanimous East West Gas Pipeline project won the Pre-Engineered Building project Award 2009 at the Infrastructure Excellence Awards, organised by CNBC-TV18 and Essar Steel. View Case Study

Aesthetic, Leak-Proof Building Impresses Client

The manufacturing facility of Technova Imaging Systems Limited at Taloja, Raigad near Navi Mumbai looks like a masterpiece on an open land surrounded by mountains. View Case Study

Unilever Partner To Win Award 2012

Unilever Partner To Win Awards 2012 was organised by Unilever South Asia Board to recognise their suppliers, who have made a significant contribution to their business. The South Asia Unilever Partner to Win Supplier Summit was held on September 5, 2012 at Mumbai. Tata BlueScope Building Solutions, a business division of Tata BlueScope Steel Limited won the award for service excellence in E-engineered steel building projects execution. Tata BlueScope Building Solutions demonstrated ’Speed with Safety’ in E-engineered steel buildings projects executed for Hindustan Unilever Limited.

Infrastructural Excellence Awards 2012

Tata BlueScope Building Solutions bagged the prestigious ‘PEB (E-engineered Building) Project of the Year award’ for the second time at the Essar Steel Infrastructural Excellence Awards in 2012. The award was conferred upon TBBS for successful execution of the ‘Coated Steel Manufacturing Plant’ of Tata BlueScope Steel at Jamshedpur. The Essar Steel Infrastructure Excellence Awards recognize the achievements of those involved in creation of India’s infrastructure and hence their contribution towards the economic development of the country.