Cutting corners can give short term gains, but severe long-term headaches! Especially within the construction industry where usage of tools, construction material and installation practices can either define or reduce the structural life of a building. Fasteners are an important consideration for both new or metal roof replacement. They may come across as non-conspicuous, easily overlooked and minor; but fasteners can hold the entire metal roof together; ensuring its long-term performance.

What is a Fastener?

A fastener is a hardware device that joins two objects together. Available in different formats such as bolts, nuts, washers, screws or rivets; fasteners are responsible for a permanent union between the roof and the purlins. These nuts and bolts used to attach the metal roof system ensure the working of a significant part of the roof performance and in turn, of the building.

Why are Fasteners the most Important part of installing a metal roof?

As the famous saying goes; ‘it’s the little things that matter’. Fasteners may seem insignificant; but holds the key to your entire roofing system. They are responsible for the overall performance of your roof and eventually the building itself. Therefore, having a good quality fastener is extremely critical. Even a small defect, can cause major disasters such as leaks and damages. Thus, fasteners are an important part of the roof installing process.

Choose an experienced roofer

Your roofer must be an experienced professional, in selecting the right fastener for your metal roofing system. The fasteners they choose should match or exceed the life expectancy of the panels that they will be used on. During a metal roof installation, a roofer must use the right kind of fasteners to make sure the roof lasts.

Consider this before making a buying decision

Before undertaking a metal roofing project or a reroofing one; you must consider the various materials and options available in the market. Considerations include the fastener material and coating, the head and washer type, the thread count and the fastener’s length.

We recommend fixing of metal cladding as under:

- For roof – it is always on crest or at the rib location and not at valley or pan

- For wall – it can be fixed on crest or valley

- For general external use in moderate to mild marine application we recommend class 3 fasteners and in severe marine climate class 4 is recommended

Remember!

The compatibility of metals is essential during a roof installation. Dissimilar metals can cause the fasteners to fail prematurely, which can lead to leakages. Even though most fasteners are made from coated metal, the choice of metal type and coating must be based on the materials the fastener is bridging together.

In construction, following stringent rules and guidelines can save money as well as lives. Compromising on sub standard material such as fastener can have graver impacts. We at Tata BlueScope Steel are here for you to make the right decision! With our specialty fasteners and other accessories for your next commercial, infra or manufacturing project; we ensure better a safe and enduring built environment!

Annexure

Fasteners recommended for Tata BlueScope Steel Products:

| Product | Appropriate Fastener Type |

|---|---|

In use more than 400 mts from severe marine influence COLORBOND® XRW steel COLORBOND® Metallic steel ZINCALUME® AZ150 steel | Fasteners conforming to AS 3566.2 – 2002 Class 3

(Note: Stainless steel fasteners are NOT recommended for use with COLORBOND® XRW steel or COLORBOND® METALLIC steel or ZINCALUME® steel.) |

In use 200 – 400m from severe marine influence COLORBOND® XRW steel In use 100 – 200m from severe marine influence COLORBOND® Ultra steel | Fasteners conforming to AS 3566.2 – 2002 Class 4

(Note: Stainless steel fasteners are NOT recommended for use with COLORBOND® XRW steel or COLORBOND® ULTRA steel.) |

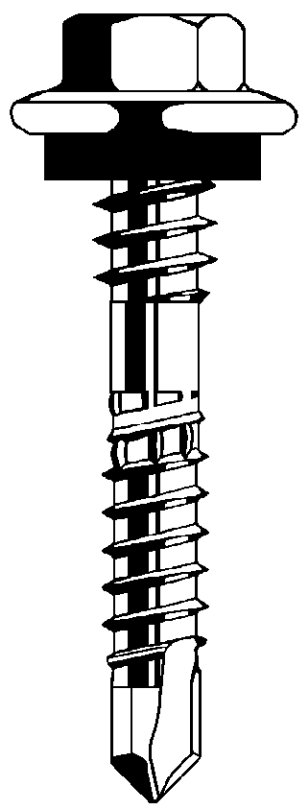

Illustrations: Correct Fasteners for Metal Cladding as per AS3566 Class 3 & 4