Light Gauge Framing System (LGFS) or Light gauge Steel framing (LGSF) is a construction technology using cold-formed steel as the construction material. It can be used for roof systems, floor systems, wall systems, roof panels, decks, or the entire buildings. They can also be used as individual framing members such as studs, joists, headers, and truss members.

Light Steel Frame members can also serve as both primary structures and secondary structures. An example of the Light Steel Framing used as primary structures is the webbed steel trusses. Steel studs act as secondary structures by providing lateral support to exterior wall finish since they rely on the primary structure for support.

Light Gauge Framing System (LGFS) buildings can be used as substitute of RCC/traditional buildings. It is used to create frames for external walls, floor, internal walls etc. These are used as the base on which suitable boards and materials are used to cover the framing. LGSF buildings look similar to traditional RCC buildings after completion

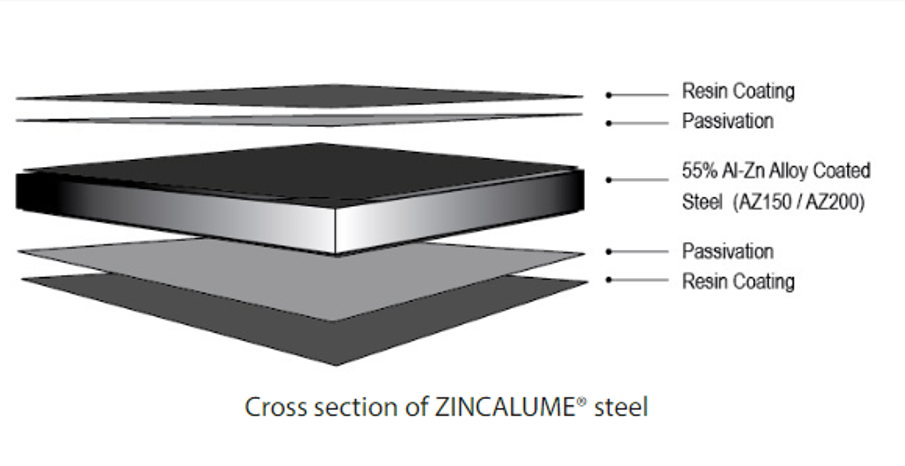

Light Gauge Steel Framing System (LGFS) made from High Strength ZINCALUME® steel Tata BlueScope Steel offers Light Gauge Steel Framing Systems made from 55% Al-Zn Alloy coated ZINCALUME® steel AZ150 G550 (550 MPa minimum yield strength), complying with AS 1397 and IS 15961.

Advantages Light Gauge Steel Framing system

- Strength & Durability: High strength results in safer structures, less maintenance. Steel structures made from High strength ZINCALUME® Steel offer greater durability, exceptional corrosion resistance and results in safer structures with less maintenance.

- Light Weight: These sections are made from light weight and high strength 550 MPa steel, and hence results in lighter foundations and buildings that have less probability of damages in an earthquake.

- Quality: Steel frames have consistent straightness and hence simplifies structural alignment. These structures are uniform in quality an thus do not warp or split.

- Recyclable: LGFS material is 100 % recyclable and hence environment friendly.

- Expansion & relocation: Ideal for expansion of existing structures, additional floors, etc. Flexibility for future expansion and relocation.

- Unequalled design flexibility: Compared to conventional framing, steel framing can span greater distances, allowing greater design flexibility. Interior walls can be placed without load-bearing considerations. Steel frames are Compatible with a wide range of cladding, roofing and glazing options.

- Lower construction costs: Light steel frames are very strong and lightweight, so building frames require less material (compared to timber or concrete). Hence results in lesser construction costs.

- Easy transportation & handling: Steel frame components are light & designed for easy to transportation and handling.

- Quick & easy construction: As all the intelligence is built into the modelling and fabrication phase of the steel frame manufacturing process, unskilled or semi-skilled labour can do the assembly and construction easily. Steel framing is supplied with electrical and service holes pre-punched, meaning reduced time on site for plumbers and electricians.

Tata BlueScope Steel offers Light Gauge Steel Framing Systems and solutions under its EZYBUILD® solutions brand

EZYBUILD® Solutions are a set of light-gauge structural buildings for industrial, commercial, residential and institutional applications. These ready to install solutions are quick alternatives to conventional buildings and are offered through a dedicated network of authorised EZYBUILD® solutions providers.

The products and solutions offered by EZYBUILD® include: PEBLite: A unique light-gauge and strong pre-engineered building solution SMARTBUILD® System: Steel Framing System with Strength and Durability SMARTRUSS® System: Advanced, lightweight framing technology for all your roof support solutions

Light gauges steel framing system has advantages like adaptability, off-site manufacturing, reusability, recyclability, cost efficiency and resource efficiency making it one of the most sustainable building methods available today. Light gauge framing systems can fulfil the requirements of small building with cost effectiveness and environment friendliness that makes light-gauge steel construction, a technology with huge growth potential and applicability.