Are you planning for a new building project and confused over which type to build? Whether to choose a Pre-Engineered Buildings or go for a conventional structure? We can help you get better insights for making an informed decision.

It is important to know the nuances of the two solutions for long-term consideration.

What are PEBS and Conventional Buildings?

Pre-Engineered Buildings

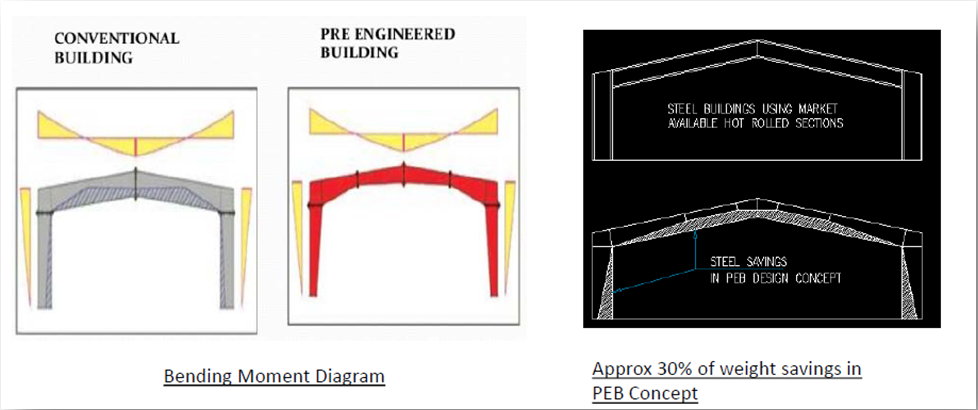

Pre-engineered buildings are built mostly in steel and are factory made, shipped to site and bolted together. The rigid framing completes the roof, beams and columns. Then other exterior panels are assembled, along with structural elements and accessories. Pre-engineered Buildings revolutionized the construction market with its built-up sections in place of conventional hot-rolled sections. Larger column-free area sets PEBs apart, compared to its conventional counterparts.

Conventional Buildings

Conventional buildings on the other hand are traditional buildings consisting of steel, brick and cement sections. These are fabricated and assembled at the site. Conventional building method involves welding and cutting, which is done largely at the construction sites. A conventional building is designed from scratch, requiring substantial designing inputs and detailing of the intricacies done by consultants.

PEB Vs Conventional – A Comparative

| Parameters | PEB | Conventional |

|---|---|---|

| Weight | 30% Lighter | Heavier |

| Structure | Primary Members are Tapered | Primary Members are hot rolled 'I' Sections |

| Design | Software-based Standard designs that are replicable | Partially Automated Designs with manual intervention |

| Secondary Members | Lightweight & rolled framed 'Z' & 'C' sections | 'I' & 'C' sections which are heavier in weight |

| Delivery Timelines | Shorter duration | Can extend depending on complexity |

| Foundation | Simple design, easy to build | Substantial investment in foundation work |

| Erection Process | Easy, Fast & Safe | Labor-intensive |

| Seismic Resistance | Low Weight Flexible Frames offer Higher Resistance to seismic forces | Relatively higher wastage and energy consumption |

| Sustainability | Reduced wastage and lesser impact on environment due to lean construction | Wastage and energy consumption |

| Flexibility | Future expansion is simple, easy, and cost-effective | Revisions or additions can be difficult due to extensive redesign |

| Performance | All components are designed to act together as a system for precision and performance | Components are designed for general use in various configurations |

| Accountability | Single source responsibility | Multiple vendors involved |

| Overall Cost | Cost is slightly more but justified from a time advantage perspective | Cost could be slightly lower but hard to determine total costs |

| Applications | Best suited for Industrial, Infrastructure, and Warehousing projects | Best suited for Commercial, Institutional, and Industrial applications |

These sections may differ along the length according to the bending moment diagram above. The use of optimal section leads to saving steel usage leading to reduction in the overall cost.

Both Pre-engineered and conventional buildings have their own advantages. Choosing the right kind of building structure depends on design requirements and materials your project demands. One must consider budget, safety, durability and maintenance before arriving at a decision.

To help you build better, we at Tata BlueScope Steel with our team of seasoned engineers and years of experience offer world-class pre-engineering building solutions in form of BUTLER® Buildings. By providing timely construction and superior solution, BUTLER® Building Solutions has achieved high acceptance in Commercial, Industrial, Infrastructure and Warehousing sectors all over the world.

Please get in touch with us on contact@tatabluescopesteel.com or visit the company website www.tatabluescopesteel.com for more information.