Roof is the most essential part of your structure. Done professionally, it seals your building, protects it from water leaks and increases your property value. Most importantly, your roof brings your entire structure to life for many years to come! The metal roofing or wall cladding is one of the principles building components that act like protective envelope.

But have you ever wondered what kind of material goes into making a steel roof?

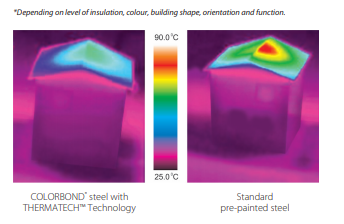

Selection of the right material would increase building life, incur low maintenance, enable thermal comfort in hot or cold seasons, provide design flexibility and improve overall aesthetics that last longer.

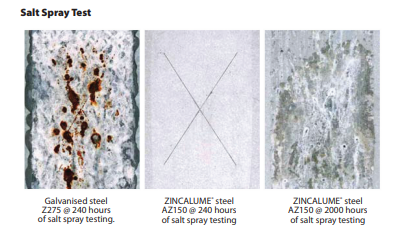

While there are many roofing materials available, ZINCALUME® steel and Galvanized steel may find themselves at loggerheads during a purchase decision.

Let us see what the differences are between the two:

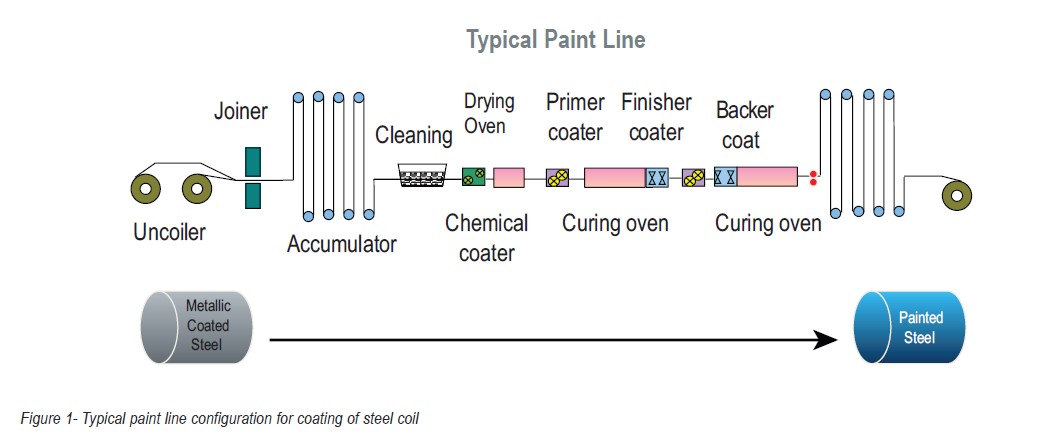

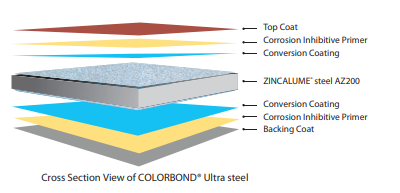

Fact file: When the steel surface is coated with an additional layer of organic or metallic material to protect from rusting, is called coated steel. Usually, a coating layer is added to flat steel when they are in a coil form.

What is Galvanized steel and ZINCALUME® steel?

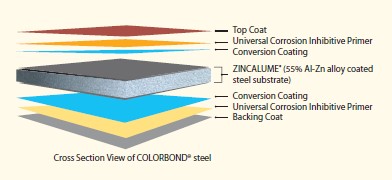

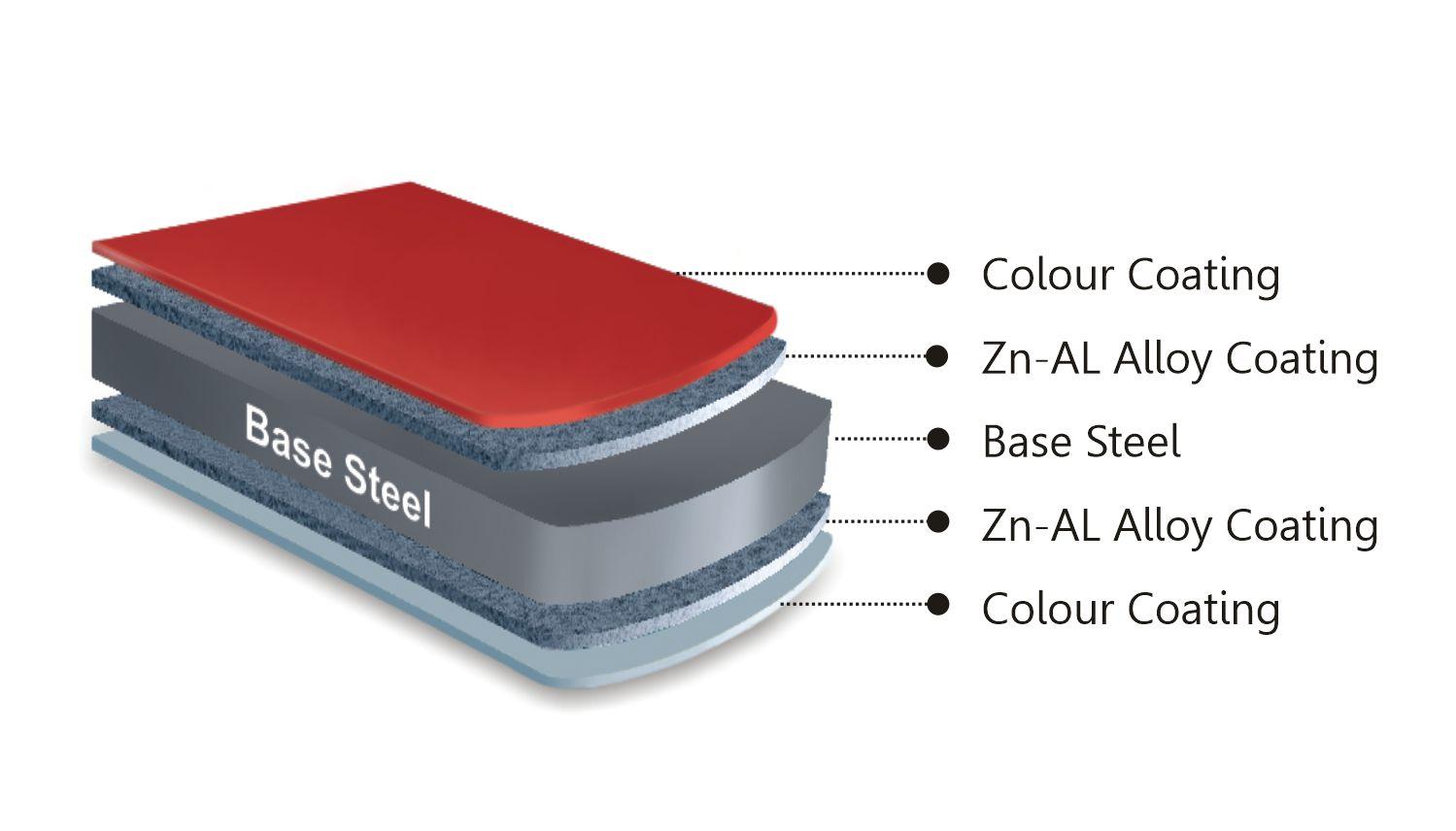

Galvanized steel is coated with almost 100% zinc while ZINCALUME® steel is coated with an alloy of approximately 55% Aluminium, 43.5% zinc and 1.5% silicon.

If you’re new to the world of steel, you may have heard the word galvanize thrown around a few times. But what does galvanize mean? Galvanizing is the process of applying a protective coating to steel or iron. The coating is made from zinc and is used to halt the formation of rust. Galvanization is important because it provides protection for steel and iron products.

Developed by technology inventors, ZINCALUME® steel on the other hand is world’s leading Al-Zn alloy coated steel product. It is an outcome of extensive research and continues to set standards for corrosion resistance and long life. It is designed to withstand the rigors of nature and the product’s performance is well-established across a wide range of climatic conditions and geographies using exposure test sites and infield inspections.

The rate of corrosion of ZINCALUME® steel is initially very similar to that of galvanized steel. However, the longer life of ZINCALUME® steel is attributed to the rapid slowing down of this corrosion rate shortly after the initial exposure to the environment. This is due to the formation of Aluminium-containing corrosion products that consequently add to the barrier protection of the coating. All the while, the zinc present in the ZINCALUME® steel coating is available to sacrificially protect the steel at cut edges.

Application areas & Advantages of ZINCALUME® steel over Galvanized steel

Galvanized steel finds its presence in Automobile, telecom & electricity towers to name few. Even in construction industry, GI sheets are practically used for carrying heavy loads. Generally, steel decking, mezzanine or primary structures like beams, columns are common applications in steel building. 1.5mm to 3.00mm are common thicknesses used for these applications. Historically, Galvanized roof panels are also being used for residential & commercial segments. Generally, Z120, Z180 & Z275 are common coating thicknesses used for construction application

With increased awareness for selecting the right material, today Architects & Developers choose ZINCALUME® steel; which has grown as a widely accepted building material over Galvanized steel especially for projects segment. Scope of ZINCALUME® steel can also be extended to LGFS, Solar mounting structures, Silos etc. where high strength & light weight along with durability is of utmost importance.

With technological development in building materials, ZINCALUME® steel is an advanced Al-Zn formulation over standalone Zn coated Galvanized steel as it offers extended corrosion protection & superior aesthetics. Having High strength to weight ratio, ZINCALUME® steel requires lesser tonnage over galvanized steel without compromising on other design aspects, resulting in reduced capital investment. For ZINCALUME® steel, AZ150 & AZ200 are most prominent coating thicknesses used for projects ie non-residential segment applications like Metro stations, Airport, Industries & warehouse as cladding material

Technical benefits of ZINCALUME® steel

Tests have demonstrated that corrosion protection of ZINCLAUME® steel can last up to four times longer than corrosion protection provided by traditional Zinc coated steel with similar coating thickness in roofing and wall cladding applications under similar environmental conditions.

Special Resin & Passivation Coating:

Specially developed Resin & Passivation, double layer protection is key differentiator for ZINCALUME® steel when compared with other coated steel peers. It adds anti darkening property by which your roof and wall cladding looks newer for a longer period. It gives excellent adhesion to substrate, very good impact resistance & forming flexibility

Self-healing properties:

ZINCALUME® steel inherently offers self-healing characteristics for cut edges. The problem with galvanized metal, painted or not, is that once it starts to red rust, it doesn’t eventually stop as it does in case of ZINCALUME® steel. The rust on galvanized surface will just continue to spread and get worse because it doesn’t have the self-healing property.

Technical support:

Tata BlueScope Steel receives extended R&D Support from BlueScope Australia and Tata Steel for special developments as per application. Full technical assistance provided by Tata BlueScope to architects, consultant, owners, Govt./Pvt organizations on recommendation of product suitability in various environments and process assistance to end users.

Since your roof is a long-term investment, it’s important to choose the best option. With decades of experience in manufacturing best-in-class steel products and solutions; we at Tata BlueScope Steel exactly know how important it is to choose the right product for your steel building. Our expert team from Tata BlueScope Steel can guide you for making the right decision, well-suited for your desired application.

For more information, please visit: https://tatabluescopesteel.com/products-solutions/zincalume-coated-steel/

Roofing options for coastal regions;

Roofing options for coastal regions;

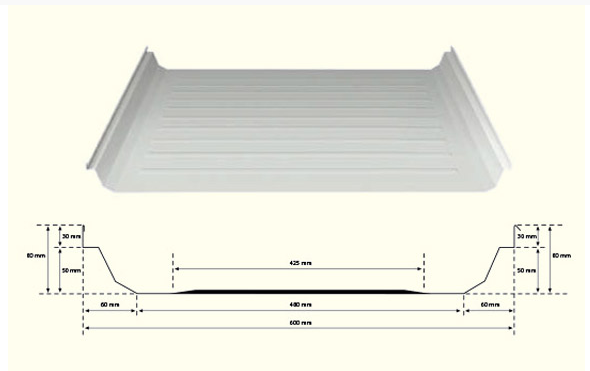

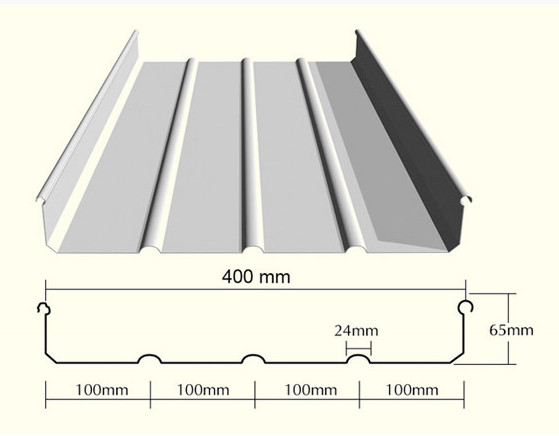

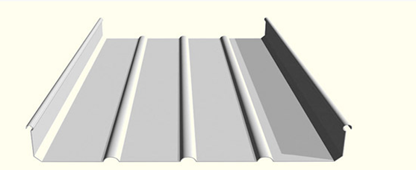

A: Standing seam roof profile

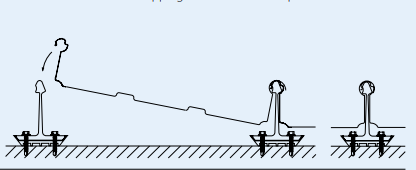

A: Standing seam roof profile  B: Concealed fixing of standing seam roof profile on clips

B: Concealed fixing of standing seam roof profile on clips